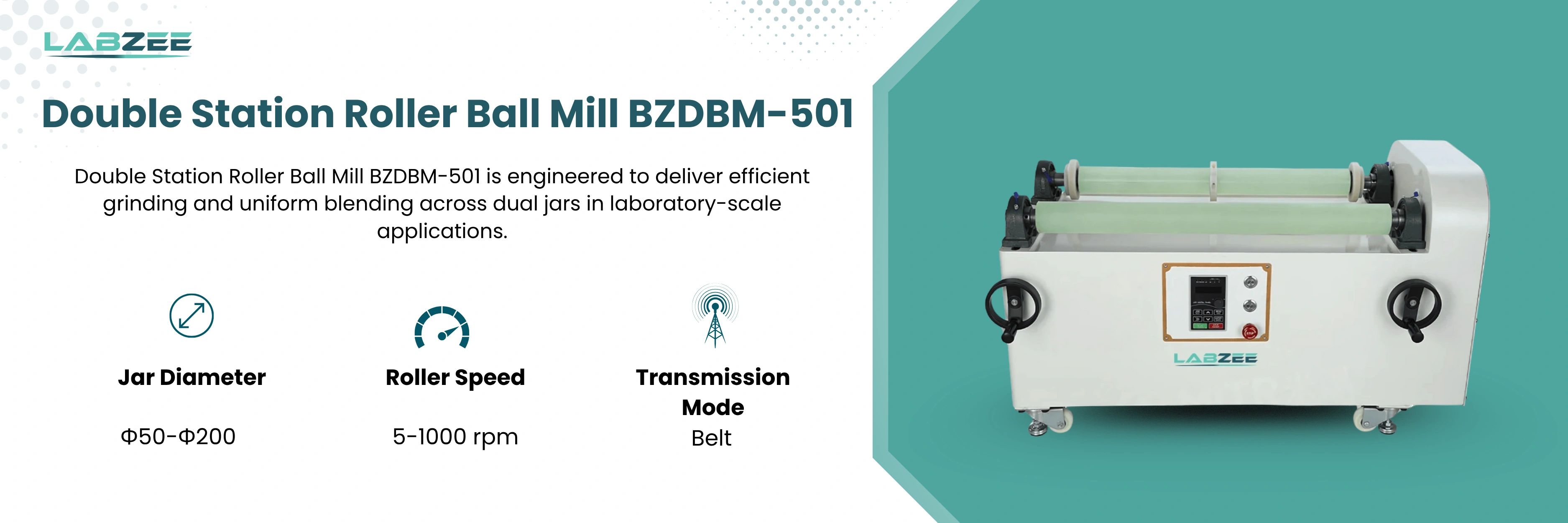

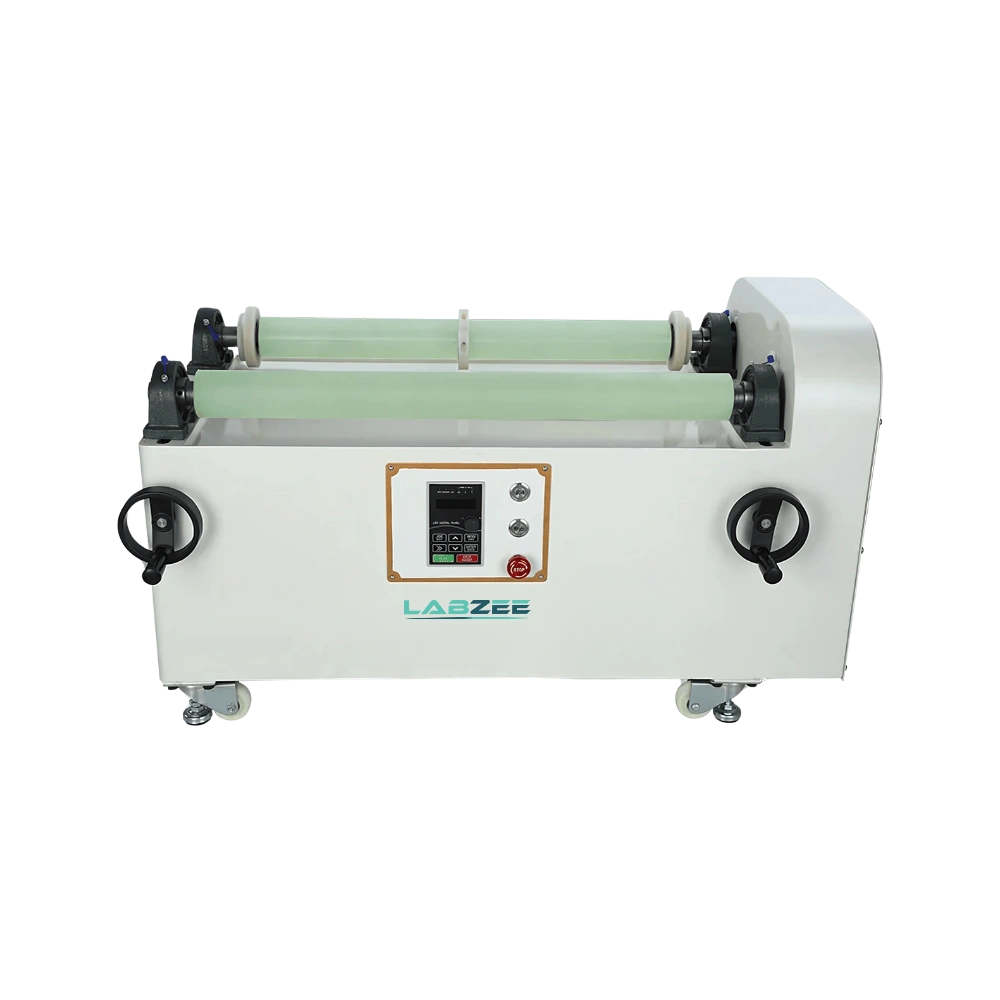

Double Station Roller Ball Mill BZDBM-501 is engineered to deliver efficient grinding and uniform blending across dual jars in laboratory-scale applications. This Mill supports a Jar Capacity of 0.5-3 L and provides precise control with roller speeds ranging from 5-1000 rpm, accommodating various processing needs. It features a stable two-roller setup, adjustable spacing by hand, and a belt-driven system for reliable performance with minimal vibration. Its compact form and dual-station flexibility make it ideal for enhancing productivity in material testing workflows. Our Double Station Roller Ball Mill BZDBM-501 is well-suited for chemical formulation, powder metallurgy, ceramic research, composite blending, and educational material science experiments.

$1,826.00

| Jar Capacity | 0.5-3 L |

| Jar Diameter | Φ50-Φ200 |

| No. of Stations | 1 / 2 |

| Roller Speed | 5-1000 rpm |

| Roller Dimension | Φ58 × 250 mm × 2 |

| No. of Rollers | 2 |

| Transmission Mode | Belt |

| Adjustable Space by Hand | 52-210 mm |

| Power Consumption | 750 W |

| Power Supply | 220 V / 50 Hz |

| Product Dimension | 94 × 50 × 80 cm |

| Net Weight | 59 Kg |

| Gross Weight | 95 Kg |

Our Double Station Roller Ball Mill BZDBM-501 offers dependable dual-jar processing ideal for parallel sample grinding and advanced powder mixing tasks. Frequently utilized in educational research labs, ceramic development units, pharmaceutical R&D, composite compound studies, and small-scale metal powder production.

Frequently Asked Questions

1: What is a Double Station Roller Ball Mill?

It’s a grinding machine with two stations, allowing you to mill two samples at once. It improves efficiency and saves time in sample preparation.

2: What materials can you grind with it?

You can grind hard, soft, brittle, or fibrous materials including ceramics, minerals, chemicals, and metals.

3: How does it work?

The jars rotate on rollers, and the balls inside them crush the material through impact and friction as the jars spin.

4: Can you run both stations at the same time?

Yes, both stations can run simultaneously, allowing parallel processing of different or same materials.

5: What types of jars can you use?

You can use jars made of stainless steel, agate, zirconia, or tungsten carbide, depending on your sample type.

6: What is a Double Station Roller Ball Mill?

A Double Station Roller Ball Mill is a type of ball mill that features two separate grinding stations. It allows for efficient grinding of two samples simultaneously, improving productivity and making it ideal for laboratory and small-scale production use.

7: Can the grinding speed be adjusted on the Double Station Roller Ball Mill?

Yes, most models of the Double Station Roller Ball Mill allow for variable speed control, enabling you to fine-tune the grinding process based on the material properties and desired particle size.

8: What types of materials can be processed in the Double Station Roller Ball Mill?

The Double Station Roller Ball Mill can process a variety of materials including ceramics, chemicals, pigments, and metal ores. It is suitable for both dry and wet grinding applications.

9: How do I ensure uniform grinding with a Double Station Roller Ball Mill?

To achieve uniform grinding, ensure that both grinding stations are filled with the correct amount of grinding media and materials. Regularly check the roller alignment and speed settings for optimal performance.

10: What safety precautions should I take while using the Double Station Roller Ball Mill?

Always follow the manufacturer's guidelines for safe operation. Ensure that the machine is properly assembled and maintained, avoid overloading the grinding stations, and wear appropriate protective equipment such as gloves and goggles when handling materials.